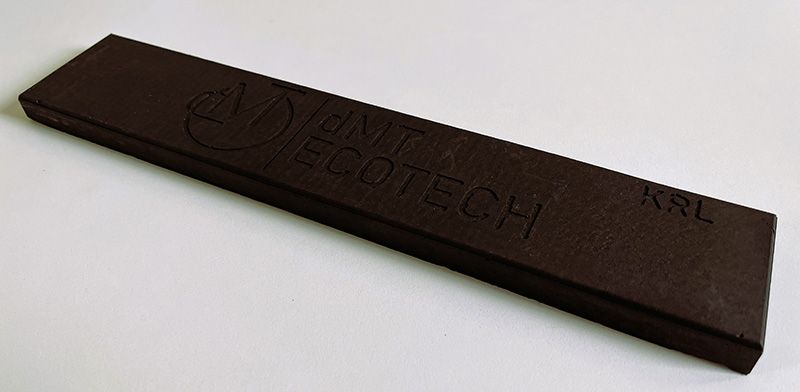

KRL®: Kiln Ring Lubricant – Effective, Safe, and Long-Lasting

Our KRL® (Kiln Ring Lubricant) solid lubricant bars provide a simple and efficient solution for the lubrication of kiln rings and support pads of rotary kilns. These lubricants are designed to reduce friction, optimize tire creep, and extend the operational life of critical kiln components.

Key Features

- High Performance: KRL® is available in various sizes and can be applied quickly and safely. It reduces friction and optimizes tire creep, providing strong adhesion to metal surfaces. The bar melts within 1-2 rotations, ensuring consistent lubrication.

- Cost-Effective: Designed with efficiency in mind, KRL® reduces maintenance costs by minimizing wear on metal surfaces and extending the life of kiln components. It also requires less frequent application compared to liquid lubricants.

- Reliable and Safe: KRL® is non-toxic, non-hazardous, and has a high auto-ignition point, making it safe to use in industrial environments. Its solid form ensures easy application without the need for additional equipment.

- Environmentally Friendly: KRL®'s precise application reduces waste and limits contamination, making your operation more sustainable.

Why Solid Lubrication Matters

Traditional liquid lubricants can be time-consuming to apply and may not provide the same level of protection as solid lubricants. KRL® offers a modern, efficient method of lubricating kiln ring and wear pad surfaces, reducing the risk of component failure and minimizing maintenance costs.With solid lubrication, you can also:

- Reduce Costs: Save time and money by extending the operational life of kiln components and reducing the frequency of lubricant application.

- Enhance Safety: Solid lubricants like KRL® lower the risks for personnel by eliminating the need for spraying liquid lubricants in hazardous areas.

- Maintain Consistency: Solid bars ensure a more even and consistent application of lubricant, leading to improved overall performance and reduced risk of under-lubrication.

- Increase Efficiency: Applying four KRL® bars in a single rotation is far more effective and efficient than applying liquid lubricants for a long period, significantly reducing maintenance time.

Adaptable for Various Industrial Applications

KRL® can be used across various industries, including cement, lime, waste management, gypsum, and many others. It ensures reliable performance in a broad range of operating environments. As demonstrated in the image above, the application process is incredibly simple - just insert the bars, and you're done.Specifications:

- Sizes: Available in various dimensions to fit all types of kilns.

- Auto Ignition Point: The high auto-ignition point of >550°C, ensures safe operation in high-temperature environments.

- Simple Application: KRL® bars are easy to insert and require no additional tools or equipment.